Quality

Reuther Mold & Manufacturing not only meets our customers’ demands for high-quality products but exceeds them. We have systems in place to ensure that the products we offer are the best in the industry. As proven by achieving the latest ISO 9001: 2015 and AS9100D: 2016 with Design certifications, Reuther Mold & Manufacturing is thorough in the steps we take to ensure quality. Additionally, our company uses high-grade technology and equipment to guarantee further that our products are up to standard.

AS9100D:2016 With Design

AS9100 is the internationally recognized quality management standard specifically written for the aerospace industry, based on the ISO 9001 quality management system (QMS) standard. Compliance with standards is confirmed through a complex auditing and certification process. Reuther Mold & Manufacturing has met the high standards expected of such operations, therefore achieving the AS9100D: 2016 with Design Certification. Through risk-based thinking, carefully monitoring performance metrics, and careful control of data, customers may be assured that every step of the production of our products is monitored from start to finish.

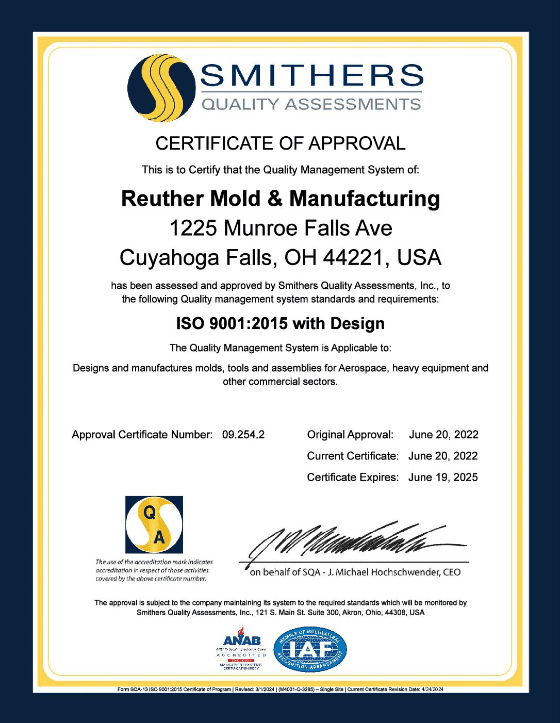

ISO 9001:2015 With Design

To meet our customers’ demands for products of the highest quality, we have achieved ISO 9001:2015 with Design certification. This program involves ongoing analysis and procedures that enable us to consistently design and manufacture products that meet customer specifications. ISO 9001:2015 with Design certification is a globally recognized standard of quality management, which our world-class processes easily obtain.

Security and ITAR Registration

The security of your CAD data and other confidential information is a high priority at Reuther Mold & Manufacturing. We are ITAR Registered and operate within full compliance with the government’s security regulations. Individual unique FTP transfer folders are available for each customer, or we can work with a customer’s existing secure data transfer site. Internally, data is transferred exclusively through a private, secure network. We know the industry and how vital security and confidentiality are to the design and manufacturing process.

Quality-Enhancing Equipment

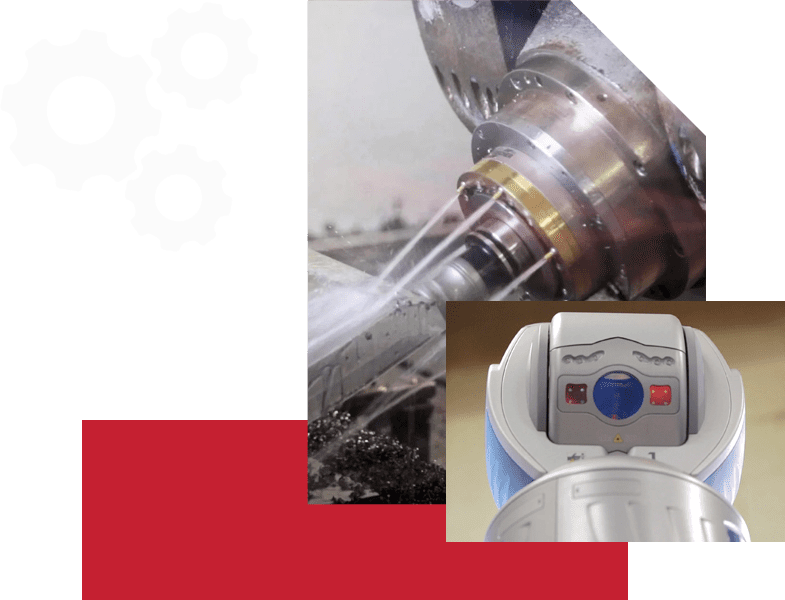

Reuther Mold & Manufacturing Invests in the best equipment the industry has to offer to maximize the level of quality we provide our customers.

Reuther Mold & Manufacturing uses the Faro Laser Tracker, which offers 230” capacity, and the Faro Inspection Arm, which has the highest resolution available. These equipment pieces allow for precise measurements without requiring additional time spent on special inspections. These measurements are directly compared to our 3D CAD data, allowing us to quickly and efficiently produce and inspect your mold as an assembly or at the individual component level.

Beyond ISO 9001:2015 With Design & ITAR Registration

In addition to our ISO 9001:2015 with Design certification & ITAR Registration, Reuther Mold & Manufacturing is certified per AWS D1.1 to weld Invar 36 plates in both MIG (GMA) and TIG (GTA) processes. Reuther Mold & Manufacturing is also certified per AWS D17.1 to weld steel and aluminum plates in MIG (GMA) and TIG (GTA) processes. Beyond these welding standards, Reuther Mold & Manufacturing is committed to meeting any additional customer-specific certifications & standards. And providing up-to-date Non-Disclosure Agreements per customer request.